The Industrial Internet of Things (IIoT) is revolutionizing industries by integrating advanced sensors and control systems into connected devices. This evolution necessitates robust, efficient, and scalable connectivity solutions. Single Pair Ethernet (SPE) connectors have emerged as a transformative technology, addressing the limitations of traditional Ethernet and wireless networks in industrial environments.

Understanding Single Pair Ethernet (SPE) Connectors

Single Pair Ethernet is an innovative technology that enables data transmission over a single pair of copper wires. This approach contrasts with traditional Ethernet, which typically requires two or four pairs of wires. SPE connectors are designed to facilitate this streamlined connectivity, offering a compact and efficient solution for industrial applications.

Advantages of SPE Connectors

1. Power over Data Lines (PoDL) Support: SPE connectors can deliver both data and power over the same pair of wires, simplifying installations and reducing the need for separate power supplies.

2. Cost Efficiency: By utilizing a single pair of wires, SPE reduces material costs and cable weight, leading to more economical and manageable installations.

3. Space Optimization: The compact design of SPE connectors minimizes space requirements, making them ideal for applications with limited installation space.

4. Enhanced Transmission Distance: SPE supports longer transmission distances compared to traditional Ethernet, enabling data transmission up to 1,000 meters without compromising signal integrity.

5. High-Speed Data Transfer: Capable of achieving transmission rates up to 1 Gbps, SPE meets the demands of modern high-speed data applications.

6. Robust Reliability: The use of shielded twisted-pair cables in SPE connectors effectively reduces signal interference and transmission loss, ensuring reliable communication.

7. Environmental Adaptability: Designed to withstand harsh conditions, SPE connectors are often waterproof, dustproof, and resistant to shock and corrosion, making them suitable for diverse industrial environments.

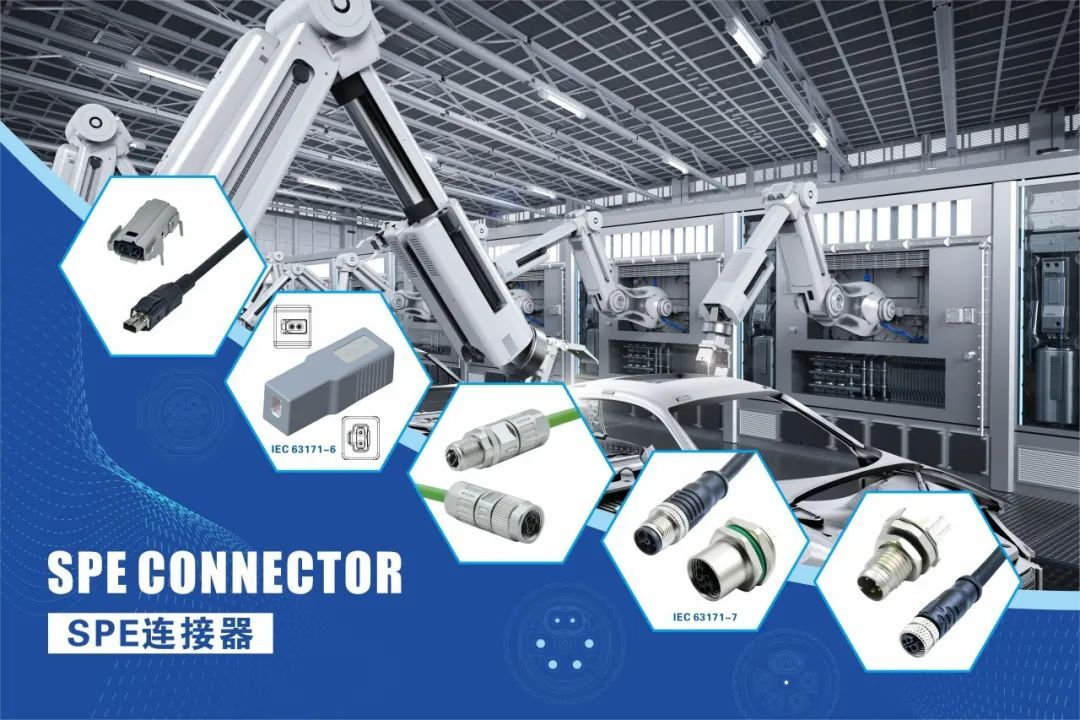

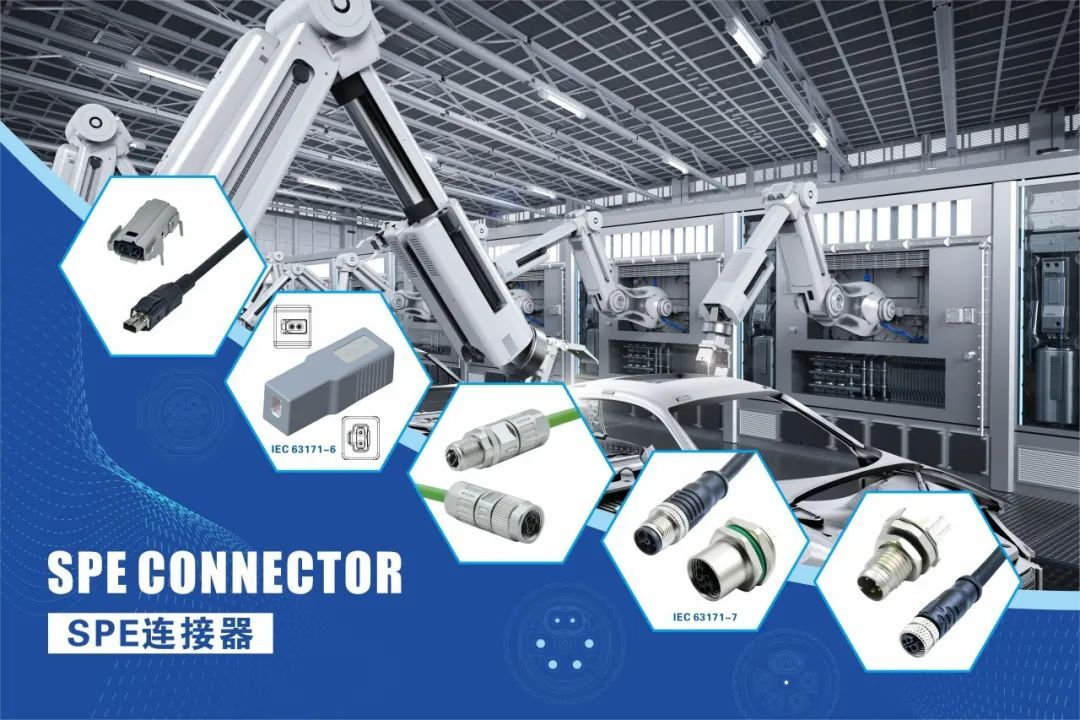

Applications of SPE Connectors

SPE connectors are versatile and find applications across various sectors, including:

· Industrial Automation: Facilitating seamless communication between sensors, actuators, and control systems.

· Automotive Industry: Enabling efficient in-vehicle networking for advanced driver-assistance systems (ADAS) and infotainment.

· Building Management: Supporting smart building technologies through streamlined connectivity of various control systems.

· Energy Sector: Enhancing monitoring and control in power generation and distribution systems.

· Transportation: Improving communication networks within railway and maritime systems.

Our SPE Product Offerings

Shenzhen SIGNAL: Advancing SPE Technology

As a member of the Single Pair Ethernet Industrial Partner Network, Shenzhen SIGNAL collaborates with industry leaders to promote and develop SPE technology. This partnership underscores the company's commitment to advancing industrial connectivity solutions and contributing to the evolution of the IIoT landscape.